What is the anti-slip performance of Crane Outrigger Pads

The anti-slip performance of Crane Outrigger Pads is crucial for crane operation safety, and its performance is influenced by many factors.

In terms of material, common outrigger pads made of rubber and polyurethane offer a good anti-slip foundation. Rubber has a certain degree of surface roughness, which increases friction between the ground and the crane outriggers. Polyurethane is not only soft but also adheres tightly to uneven surfaces, further enhancing its anti-slip properties.

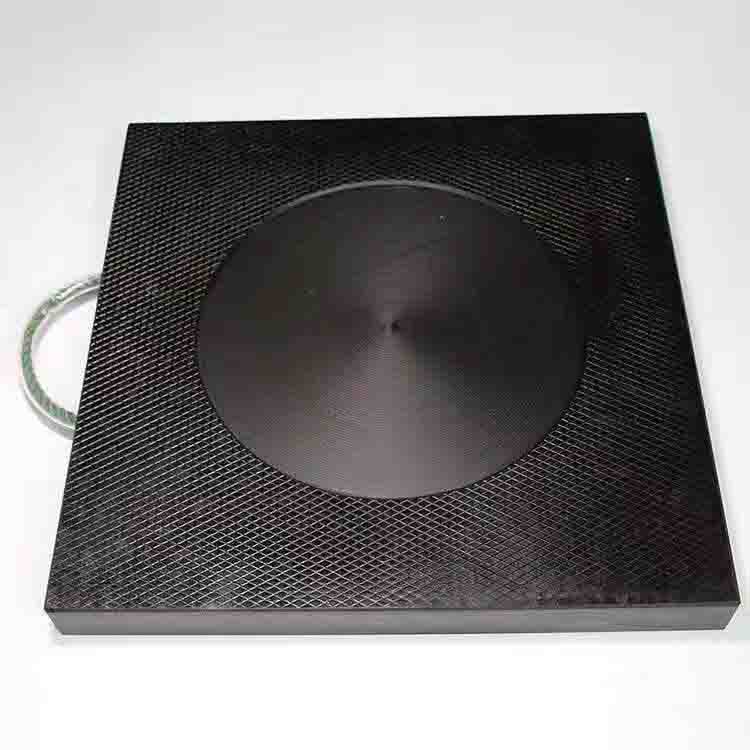

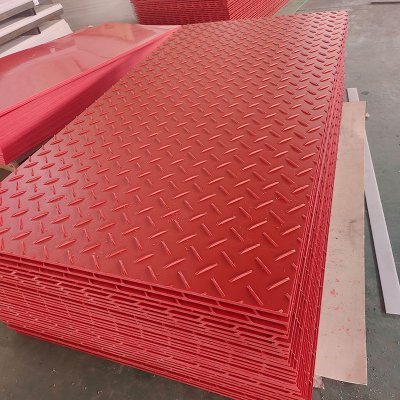

In terms of design, some outrigger pads feature anti-slip patterns or raised ridges. These specialized features penetrate tiny crevices in the ground, enhancing grip and preventing slippage during the high pressure and vibration generated by crane operation.

However, anti-slip performance is also affected by surface conditions. Crane Outrigger Pads provide excellent anti-slip performance on dry, flat, and firm surfaces; however, their anti-slip effectiveness is significantly reduced on wet, soft, or oily surfaces. Therefore, the surface should be cleaned and evaluated before use, and if necessary, additional friction-enhancing measures can be implemented to ensure safe crane operation.