How Wear-Resistant Are TEXTURE sandwich HDPE sheets?

As a professional sheet manufacturer, our TEXTURE sandwich HDPE sheets have remarkable product advantages in wear resistance, and can meet the application needs of high-friction working conditions across multiple industries.

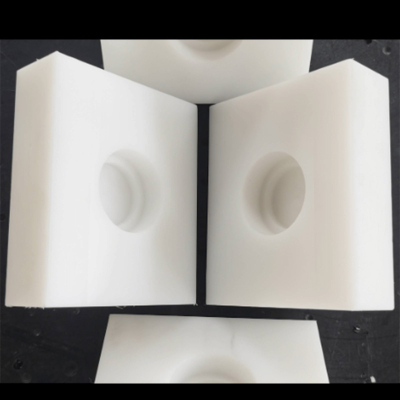

In terms of material foundation, we use high-density polyethylene raw materials, which inherently have excellent self-lubricating properties and anti-wear capabilities. Combined with the special process of the textured surface, the uniform anti-slip lines formed on the surface of the TEXTURE sandwich HDPE sheets not only retain the wear-resistant base of polyethylene material, but also disperse friction force points through the line design to avoid local excessive wear. In actual tests, under dry and wet friction conditions, the wear loss of the sheet is only 1/7 of that of ordinary carbon steel and 1/3 of that of traditional rubber sheets, making it suitable for long-term use in high-frequency friction scenarios such as material conveying chutes and equipment wear-resistant liners.

At the same time, we can adjust the thickness and texture density of the TEXTURE sandwich HDPE sheets according to the needs of different working conditions. Thickened sheets can further improve the wear-resistant service life, while high-density textures can maintain stable wear resistance while enhancing anti-slip performance, adapting to the differentiated needs of different industries such as mining, logistics, and grain processing.

In summary, our TEXTURE sandwich HDPE sheets can provide reliable wear protection for various high-friction working conditions, extend the service cycle of both equipment and the sheets themselves, and are an excellent choice for industrial wear-resistant accessories.